Water Bath Heater for Fuel Gas

Snapshot

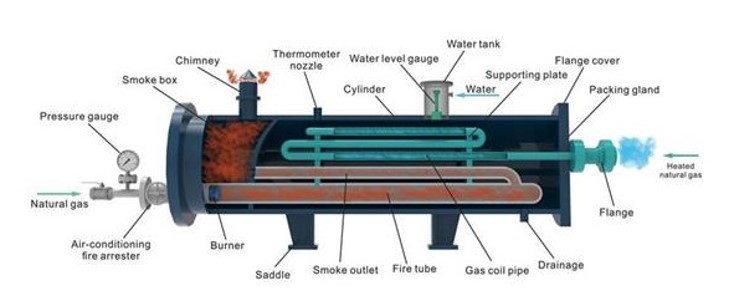

Water bath heater for fuel gas is a crucial component in various industrial processes, designed to efficiently and safely heat fuel gases before they enter the main processing system. This specialized heating system utilizes the principle of indirect heating, where the fuel gas flows through a coil or tube submerged in a bath of heated water.

The water bath serves as a heat transfer medium, ensuring a gradual and controlled elevation of the fuel gas temperature. This method prevents direct contact between the heating source and the gas, minimizing the risk of combustion or undesirable chemical reactions.

Water bath heaters are particularly employed in the oil and gas industry, where they play a vital role in preheating natural gases, liquefied petroleum gases (LPG), or other hydrocarbon streams, enhancing their flow characteristics and optimizing downstream processes.

The versatility and efficiency of water bath heaters make them integral for maintaining operational integrity and efficiency in diverse industrial applications.

Typical Applications

Natural Gas Processing

Fuel Gas Conditioning

Hydrocarbon Liquid Heating

Chemical Processing

Water and Wastewater Treatment

Food and Beverage Industry

HVAC Systems

Pulp and Paper Industry

Power Generation

General Industrial Processes

Standard Features  Efficiency and Reliability:

Efficiency and Reliability:

Individually removable fire-tubes for easy maintenance and inspection.

Stainless steel flue gas stack ensures durability and corrosion resistance.

Anti-reverse draft diverters prevent backflow and protect against weather elements.

PLC control system provides precise temperature regulation and automation.

Safety and Quality

Multi-mitered fire-tube bends reduce stress and improve heat transfer.

Positive seal flange designs ensure leak-free operation.

Bath media expansion reservoir prevents overflow and maintains optimal levels.

Heat media temperature indicator for real-time monitoring.

Shell and tube-bundle design comply with industry standards (API 12K and ASME-8-1).

100% radiography on process tube-bundle welds guarantees structural integrity.

Advantages

Indirect Heating: No direct contact between the heat source and the heated material, minimizing contamination risks.

Uniform Heating: Ensures consistent temperature distribution throughout the heated substance.

Efficient Heat Transfer: Maximizes energy efficiency and reduces operating costs.

Precise Temperature Control: Allows for accurate regulation of the heating process.

Safety: Reduces the risk of fire or explosion compared to direct heating methods.

Ease of Maintenance: Simple design and accessible components facilitate regular inspections and repairs.

Compatibility with Impurities: Can handle materials containing contaminants without significant performance degradation.

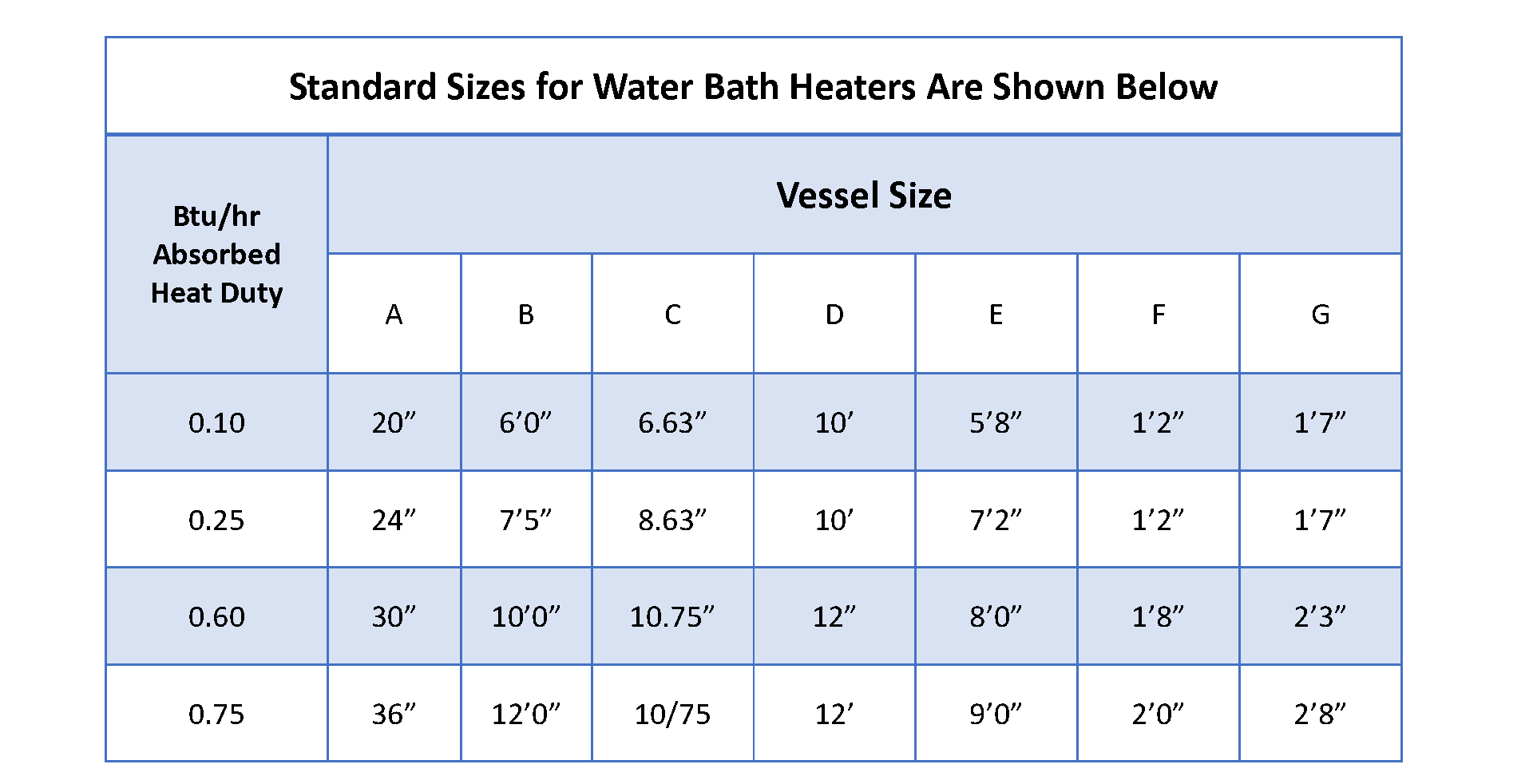

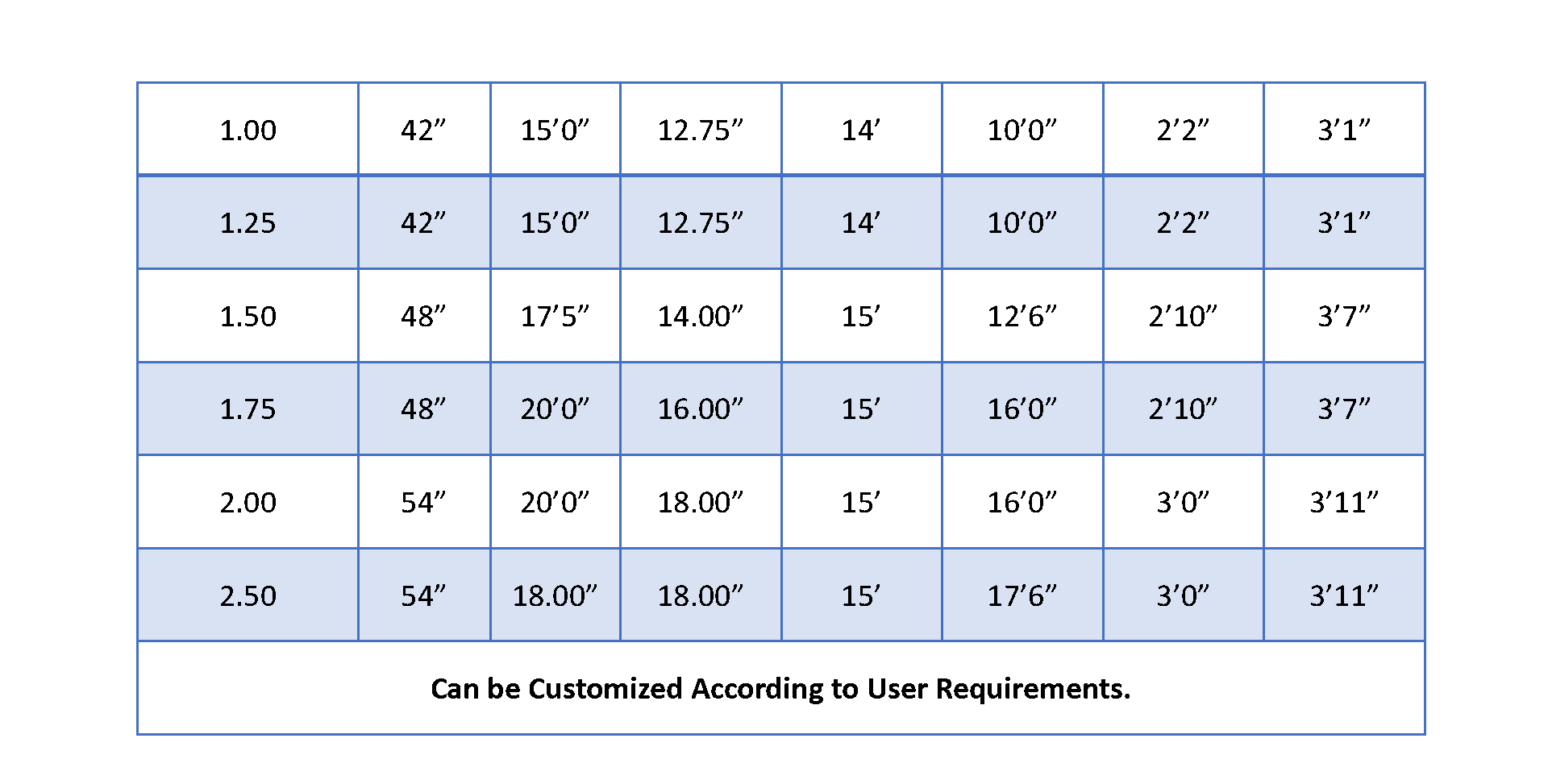

Customization and Sizing

We offer a range of standard sizes for our water bath heaters. However, we also specialize in customizing units to meet your specific needs, ensuring optimal performance and efficiency.