Capability Offerings

MEDAS along with its principal partner H+R provides one-stop solutions for enclosures: from Acoustic Design Calculations, Engineering, Detailed Design, Manufacturing and Site Delivery, services like Acoustic Consultancy, Acoustic Measurements as well as Installation and Commissioning can be included in the scope of supply.

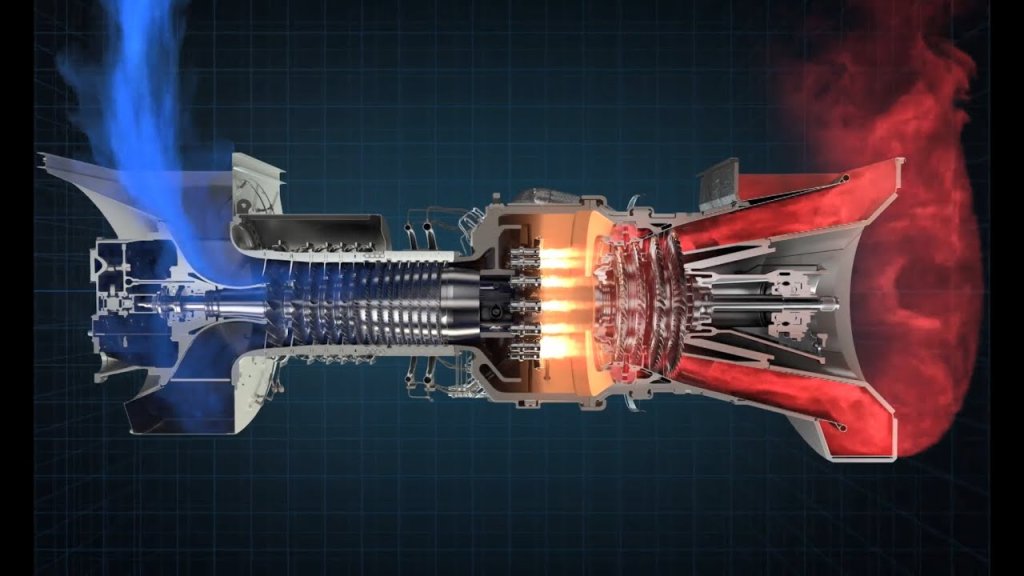

Gas Turbine

Transformers

Compressors

Turnkey

Gas Turbine Package

Our gas turbine enclosures are a combination of standardized design with some modular add-ons to meet specific project requirements and to provide the ideal solution for our clients.

Transformer Enclosures

Enclosures for transformers are tailor-made to reduce humming noise from power transformers, synchronous compensators, deicers, and other noisy equipment.

Compressor & Generator Enclosures

Customized design & supply as per requirements: High-performance acoustic louvre air inlet; Exhaust air attenuator (left side of the enclosure); Lockable double access/service doors; BS or RAL painted color; Internal absorption Roof with a fall back to front

One stop solution

Our range of services spans from dimension calculations and engineering designs to comprehensive acoustic assessments, manufacturing, and installation.

Acoustic Enclsoures for Transformers

We specialize in tailor-made screens and enclosures for transformers, aiming to diminish the humming noise generated by various equipment, including power transformers, synchronous compensators, and deicers. These structures are crafted using absorbent steel panels that have undergone rigorous laboratory testing, ensuring optimal reduction of low frequencies and effective acoustic control. Known for their remarkable durability, these enclosures have earned the trust of prominent industry players like Siemens, ABB, General Electric, Alstom, and Hydro-Québec.

Guaranteed acoustic performance

Superior quality and durability

By submitting, you consent to MEDAS processing your information in accordance with our Privacy Policy. We take your privacy seriously; opt out of email updates at any time.

This site uses cookies and analytics therefore protected by Google Privacy Policy and Terms of Service apply.